Product Details

Specifications

| Technical Data | VT-U1 |

|---|---|

| Washing capacity (basket/h) | 40 |

| W x D x H (mm) | 600 x 600 x 825 |

| Maximum washing height (mm) | 310 |

| Rack size (mm) | 500 x 500 |

| Heater Type | Electrical Heater |

| Washing tank heater power (kw) | 4.5 |

| Booster content (liter) | 5 |

| Booster heater power (kw) | 4.5 |

| Default rinse cycle (s) | 10 |

| Rinse usage (L/rack) | 2 |

| Max water flow (liter / hr) | 100 |

| Electrical loading (kw) | 5.12 |

| Water inlet temp. | > 50 degrees C (suggested) |

| Water inlet hose | 3/4 |

| Drain pipe (mm) | 25 |

| Water flow pressure (kg) | 0.5 - 2 |

| Net weight | 70 |

| Breaker (Amp.) when 220V/1+G | 30 |

| Breaker (Amp.) when 380V/3+G | 10 |

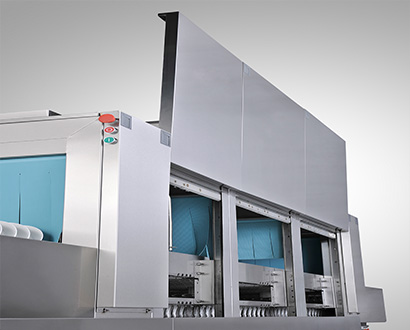

Features

Energy saving control system

- Stainless steel electronic control module mounted at eye level

- Automatic exhaust air system

- Automatic self-cleaing system

- Pre-wash tank temp.:45-55℃,wash tank temp.:62-65℃,power rinse tank temp.:65-70℃ final finse temp.:at least 80℃.Energ saving infrared sensor control activates rinse pumps and dryer, create saving 360l/h maximum

- Optional to equiped with heat recovery re-circulation system

High-efficient designs

- Tailor-made design of tank quantity,heat dryer,sharp blower,double rinsing.There are various options for your choose according to special requirements

- Multiple protection switch designs,automatic and manual energy saving system

- Every tank,dryer,double rinse tank has sight door for easy maintenance.

- Adopt such as ABB,ASCO,RAINBOW,SCHNEIDER Electric and LG international brands parts

- Tailor-made height and width according to dimension of utensils being washed

- Stainless steel pumps motor and impeller

Safety performance

- Conveyor belt speed can be controlled by frequency transformers (two options). F-2 2meter/minute.F-3 2.5meter/minutes,F-4 3meter/minute maximum

- OFN/OFF switch and emergency button at entry and exit of the equipment

- Emergency alarm

- Automatic locking mechanism

- Multiple protection switch designs,automatic and manual energy saving system

- All double wall construction of sight doors prevents burn and heat loss

Controllable operations

- Two heater type options,electrical heating and steam heating.

- Two speed options and two dyer section for choice.

- All in one design for stainless steel wash arms and rinse arms, easy to maintain

- Conveyor directio

Download

- VT-F Datasheet

- VT-F Operation manual

- Dispenser 420L Installation and operation manual

- Dispenser 200L Installation and operation manual

Optional

| Items | Status |

|---|---|

| Force Cold Dryer | Optional |

| Conveyor extra length per30 or 60cm | Optional |

| Heat recovery re-circulation system | Optional |

| Physical scale shield | Optional |

| Double rinse | Optional |

| Pre rinse | Optional |

| Double injection dispenser (ECOSTAR420L) | Alternative |

| Single injection dispenser (ECOSTAR200L) | Alternative |

Request A Quote

Please fill out the form below and a Prowell representative will contact you with more information as soon as possible.