Product Details

Specifications

| Technical Data | VT-U1 |

|---|---|

| Washing capacity (basket/h) | 40 |

| W x D x H (mm) | 600 x 600 x 825 |

| Maximum washing height (mm) | 310 |

| Rack size (mm) | 500 x 500 |

| Heater Type | Electrical Heater |

| Washing tank heater power (kw) | 4.5 |

| Booster content (liter) | 5 |

| Booster heater power (kw) | 4.5 |

| Default rinse cycle (s) | 10 |

| Rinse usage (L/rack) | 2 |

| Max water flow (liter / hr) | 100 |

| Electrical loading (kw) | 5.12 |

| Water inlet temp. | > 50 degrees C (suggested) |

| Water inlet hose | 3/4 |

| Drain pipe (mm) | 25 |

| Water flow pressure (kg) | 0.5 - 2 |

| Net weight | 70 |

| Breaker (Amp.) when 220V/1+G | 30 |

| Breaker (Amp.) when 380V/3+G | 10 |

Features

Energy saving control system

- Adopt ASCO solenoid valve,and Schneider's electrical parts.Additional over-load contactor to protect the machine from abnormal power supply.

- Newest electric control panel and heater layout design.One piece steel,100% SUS304 material.Attractive and durable.

- Timerauto energy saving function and emergent safety switch

- Washing and rinsing temperature is controlled by the most advance thermostats(LED system)

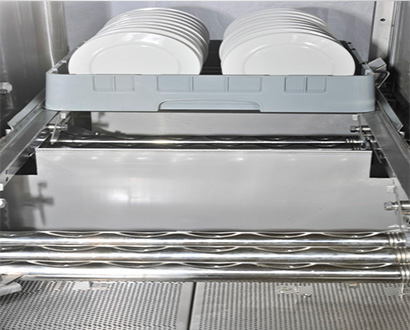

High-efficient designs

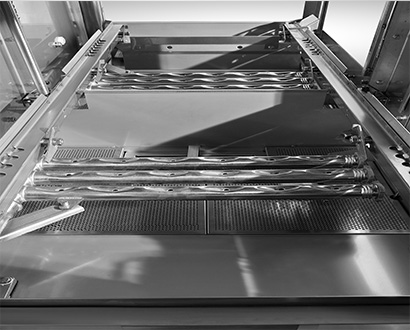

- CAD stainless steel washing arms.Powerful washing force,effective washing angle,and large washing scale,to reach perfect washing quality.

- 19cm between washing gutter and final rinsing position

- Special process washing arm

- Heater has safe water level system

- Both washing and rinsing heater has over-heating protect system

- Three phrase 220V/380V sharing transformer system

- Special plastic foat-ball processed by cold welding technology

Safety performance

- Switzerland ABB motor and stainless pump body,guarantee cleaning quality.

- Both electrical heating(E) and steam heating(S),can guarantee 60-65℃ washing temperature,and higher than 80℃ rinsing temperature

- Protect system starts when low water level.No-fuse switch

- Qualified heat insulating material reduces heat loss from the booster

Controllable operations

- Every model has automatically and manually convert function.Rack stands auto-timing engergy save system

- R2E/S main parts are to maintained from top or front of the machine

- Easy disassembly filter leaving separate rack,washing arms and curtain make maintain easier.

- Electrical and steam heater optionsp

Download

- VT-R2 Datasheet

- VT-R2 Operation manual

- Dispenser 420L Installation and operation manual

- Dispenser 200L Installation and operation manual

Optional

Optional

| Items | Status |

|---|---|

| Conveyor extra length per 60cm | Optional |

| Heat recovery re-circulation system | Optional |

| Double rinse section | Optional |

| Dyer | Optional |

| 90° Corner Dyer(steam/electric) | Optional |

| 90° Corner table | Optional |

| Physical scale shield | Optional |

| Double injection dispenser (ECOSTAR420L) | Alternative |

| Single injection dispenser (ECOSTAR200L) | Alternative |

Request A Quote

Please fill out the form below and a Prowell representative will contact you with more information as soon as possible.